Your bag is empty

Don't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign inDon't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign inDon't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign inDon't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign inDon't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign inThe KOSO Board production plant utilizes world-renowned German technology, specifically the 8th Generation Siempelkamp ContiRoll® Press. This cutting-edge press is the latest model from Siempelkamp and serves as the core element of the particle board forming and pressing line. The ContiRoll® Press features nearly isobaric pressure distribution, with patented pressure distribution plates ensuring consistent pressure along the working direction, enhancing product quality and performance.

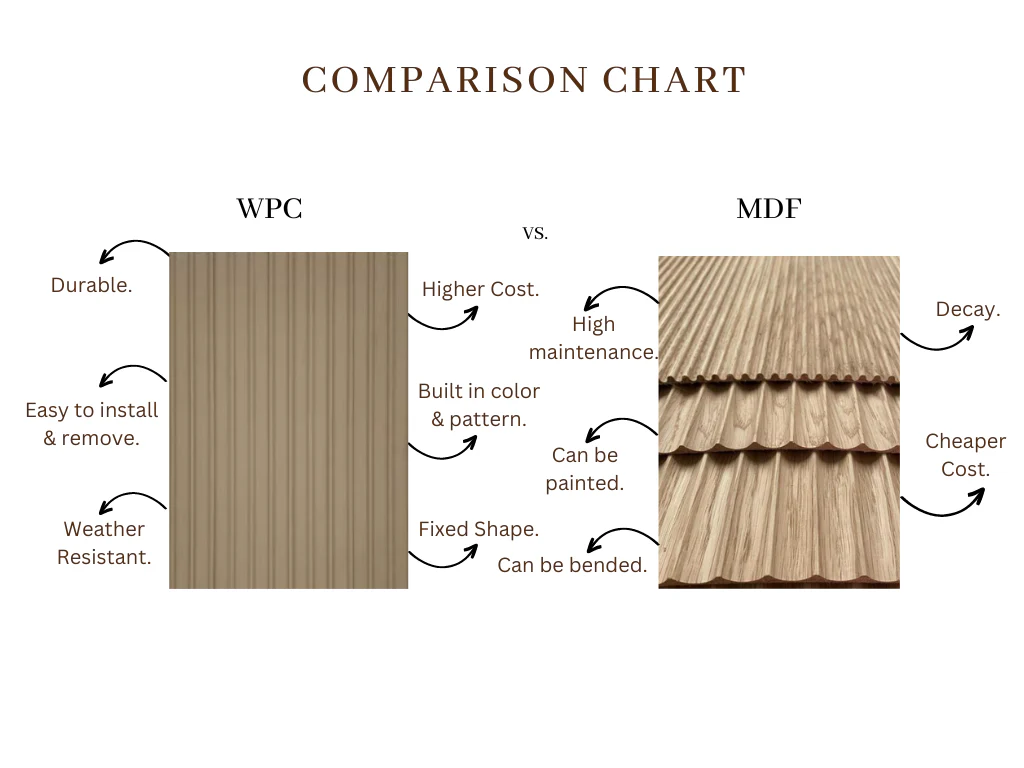

WPC is a sustainable and versatile material made by combining wood fibers or wood flour with thermoplastics (such as PVC, PE, or PP) and additives. It is widely used in construction and manufacturing due to its durability, water resistance, and low maintenance requirements.

Durability: Resistant to weather, moisture, and insects, making it ideal for outdoor use.

Eco-Friendly: Often made from recycled materials, reducing waste and environmental impact.

Low Maintenance: Unlike natural wood, it does not require frequent painting or sealing.

Versatility: Used in decking, fencing, cladding, furniture, and more.

Aesthetic Appeal: Available in various textures and finishes, resembling natural wood.

WPC combines the best properties of wood and plastic, making it a popular choice for modern, sustainable building solutions.

WPC (Wood Plastic Composite) differs significantly from traditional materials like wood and plastic. Unlike natural wood, WPC is highly resistant to moisture, rot, and termites, making it more durable and low-maintenance. It eliminates the need for regular painting or sealing, offering a longer lifespan with minimal upkeep. Compared to pure plastic, WPC combines the strength and stiffness of wood fibers with the versatility of plastic, resulting in a material that is both robust and aesthetically pleasing. Additionally, WPC is eco-friendly, often made from recycled materials, making it a sustainable alternative to conventional options.

Boards: WPC boards are versatile and used in furniture making, cabinetry, and partitions.

Worktops: Durable and water-resistant WPC worktops are ideal for kitchens, bathrooms, and other surfaces.

Wall Panels: WPC wall panels provide an elegant and modern finish, suitable for both interior and exterior walls.

These products demonstrate WPC’s versatility and suitability for diverse applications in construction and design.

Composition and Material Properties

WPC (Wood Plastic Composite) is made from a mixture of wood fibers or sawdust combined with thermoplastic polymers like PVC. This combination gives WPC superior durability and resistance to moisture, decay, and pests, making it ideal for outdoor applications. The plastic component of WPC makes it less prone to warping or swelling, which is a common problem in materials exposed to water. As a result, WPC is often used in decking, cladding, and garden furniture, where resistance to the elements is crucial.

Applications and Suitability

MDF (Medium Density Fiberboard) is created by compressing wood fibers with a resin binder under heat and pressure, resulting in a dense, smooth surface. It is highly favored for indoor applications such as cabinetry, furniture, and interior paneling due to its fine, smooth finish that is ideal for painting or veneering. However, MDF is more vulnerable to moisture and can swell or degrade if exposed to water, which makes it unsuitable for outdoor use. While WPC is designed for longevity in wet environments, MDF excels in interior design where aesthetic appeal and a smooth, workable surface are priorities.

Our MDF technology incorporates cutting-edge processes to produce high-quality, durable, and sustainable Medium Density Fiberboard. Utilizing a sophisticated blend of wood fibers, resins, and advanced compression techniques, we create MDF panels with superior consistency, density, and strength. Our technology ensures that each panel has a smooth, uniform surface ideal for applications such as furniture, cabinetry, and interior paneling. The use of precision equipment allows for customizable thicknesses and sizes, ensuring that our MDF products meet the specific needs of our clients.

Additionally, our commitment to sustainability is reflected in the use of eco-friendly adhesives and wood sourced from responsibly managed forests. The advanced technology behind our MDF production ensures minimal waste, efficient use of resources, and a lower environmental footprint. By combining innovation with environmental consciousness, we provide a high-performance product that meets the growing demands of modern construction and interior design while upholding the highest standards of quality and sustainability.

We’re disrupting the building materials industry by combining eco-friendly innovation with cutting-edge technology. For every product you buy, we plant a tree, ensuring that your purchase helps restore the planet. Our wood composite products are designed to last a lifetime, giving you durability and style while leaving a lighter footprint.

Sustainable, planet-friendly materials.

Products built to last a lifetime.

High-quality at half the price of competitors.

Visualize your space using our AR technology.

I just visited the Koso website for the first time and found it to be pretty informative. However, I noticed some sections didn’t load correctly on mobile. Hopefully, that gets sorted out soon. Otherwise, it’s a solid platform, and I look forward to seeing more updates!

While the Koso website has a lot of great content, I think it could benefit from a more modern design and a clearer layout. Some pages are a bit cluttered, which makes it harder to find specific information. A little redesign and more prominent call-to-action buttons could really improve the experience.

I’m really impressed with the Koso website! It’s easy to navigate, the design is clean, and the information is well-organized. The user experience is fantastic, and I especially love how fast everything loads. It’s clear a lot of thought went into making it intuitive. Keep up the great work!

Koso elevates your home while protecting the planet. Build smarter, live greener, with our disruptive approach to modern construction.

Copyright © 2024 KOSO.All rights reserved

Don't miss out on great deals! Start shopping or Sign in to view products added.

Shop What's New Sign in